- +971 43807099

- +971 563244963

- brisunco@emirates.net.ae

Edit Content

- Meet Us

Shed No. 10,

Fresh Express Warehouse, Road B1, DIP 1,

Dubai, UAE.

Shed No. 10,

Fresh Express Warehouse, Road B1, DIP 1,

Dubai, UAE.

New

New

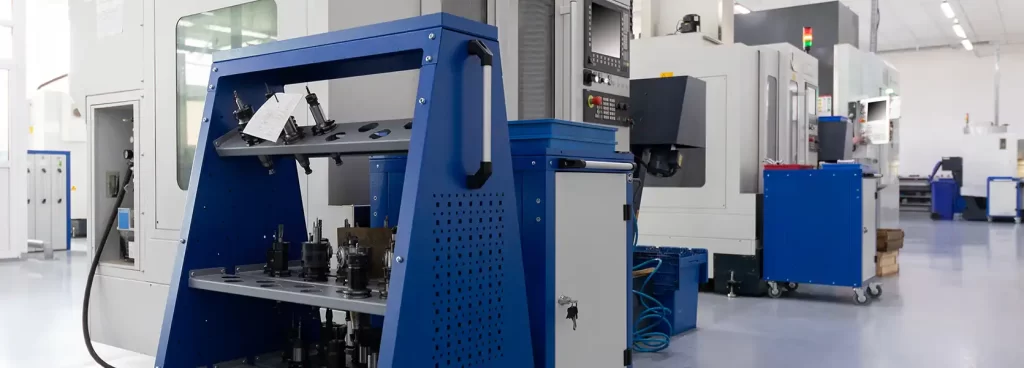

The manufacturing landscape is continually evolving, driven by technological advancements that enhance precision, efficiency, and capabilities. At the heart of this transformation are Computer Numerical Control (CNC) machines. These intelligent workhorses, which power much of the precision work done by leading metal fabrication services like Brightsun Industries, are not static; they are at the forefront of a dynamic future.

Understanding the emerging trends and innovations in CNC technology is crucial for any industry looking to maintain a competitive edge.

At a Glance

One of the most significant trends shaping the future of CNC machines is their deeper integration into the broader ecosystem of smart manufacturing, often referred to as Industry 4.0. This involves connecting CNC machines with other systems and technologies to create highly automated, data-driven production environments.

We are witnessing a shift towards machines that are not only automated but also intelligent and interconnected. CNC machines are increasingly equipped with sensors that collect vast amounts of data on their performance, tool wear, and part quality. This data is then transmitted to central systems for real-time analysis.

The goal is to create “digital twins” of machines and processes, allowing for predictive maintenance, optimized production schedules, and rapid identification of potential issues before they lead to downtime. This integration means less human intervention is needed for routine monitoring, allowing skilled operators to focus on more complex tasks.

While CNC machines are inherently automated, the future promises even higher levels of automation through greater collaboration with robotics. This trend is moving beyond simple loading and unloading tasks.

Innovations allow robots to work seamlessly alongside CNC machines, performing intricate tasks like deburring, polishing, inspection, and even adaptive fixturing. This collaborative approach significantly reduces cycle times and improves consistency by minimizing manual handling errors. Furthermore, the integration of robotic arms with vision systems enables CNC machines to handle more complex parts with greater flexibility, adapting to variations in material or design without requiring extensive retooling. This means greater output and a more versatile manufacturing process for various metal fabrication services.

The power of Artificial Intelligence (AI) and Machine Learning (ML) is beginning to revolutionize CNC machining. These technologies are poised to elevate CNC capabilities beyond what traditional programming allows.

AI algorithms can analyze the vast datasets generated by CNC machines to identify patterns and optimize parameters in real time. This can lead to improved cutting speeds, extended tool life, and enhanced surface finish. Machine learning models can predict potential machine failures, enabling proactive maintenance that prevents costly breakdowns. AI can assist in generating more efficient toolpaths, reducing material waste and energy consumption. This intelligent optimization translates directly into cost savings and superior product quality for companies specializing in steel and metal fabrication.

The future of CNC machines is inherently connected. The widespread adoption of the Internet of Things (IoT) means that CNC machines are becoming crucial “things” on the network, facilitating seamless data exchange.

Cloud-based solutions are gaining traction, allowing manufacturers to remotely monitor machine performance, manage production schedules, and even upload new programs from anywhere in the world. This enhances flexibility and responsiveness, particularly for companies operating multiple facilities or managing complex supply chains. Secure cloud platforms also facilitate collaboration, enabling engineers and technicians to access and analyze machine data from different locations, fostering a more agile and efficient workflow for all types of metal fabrication services.

While subtractive manufacturing (cutting away material) has been the domain of CNC machines, the lines are blurring with additive manufacturing (3D printing). The future will see more hybrid systems emerging.

These innovative machines combine the precision of CNC machining with the versatility of additive processes. For example, a single machine might be able to print a part and then precisely machine its surfaces to achieve exact tolerances, all in one setup. This allows for the creation of previously impossible and incredibly complex geometries while also reducing material waste. Such hybrid systems offer manufacturers unprecedented design freedom and open new avenues for rapid prototyping and specialized production, pushing the boundaries of what is possible in metal fabrication.

The future of CNC machines is dynamic and exciting, promising greater automation, intelligence, and connectivity. These trends are not just theoretical; they are actively shaping how modern manufacturing operates, offering unparalleled opportunities for efficiency, precision, and innovation.

For us at Brightsun Industries, staying abreast of these developments is not merely an option; it is a strategic imperative to continue delivering cutting-edge metal fabrication services.

Contact us now to join us in the future of CNC machines.

Q1: How will AI impact the job roles for CNC machine operators?

AI will likely shift the focus of CNC operators from routine machine tending to more supervisory roles, involving monitoring AI-optimized processes, problem solving, and programming complex tasks. It will emphasize skill development in data analysis and system management.

Q2: What are the main benefits of integrating CNC machines into an Industry 4.0 environment?

The main benefits include real-time data analysis for improved decision making, predictive maintenance to minimize downtime, optimized production schedules, enhanced quality control, and greater overall operational efficiency.

Q3: Can existing CNC machines be upgraded to incorporate these new technologies?

While not all older machines can support every innovation, many modern CNC machines can be retrofitted with sensors and connectivity modules to enable data collection and basic integration into smart manufacturing systems. Significant upgrades may require newer models.

Q4: How do hybrid CNC and additive manufacturing systems benefit industries?

Hybrid systems offer benefits such as the ability to create highly complex geometries, reduced material waste, faster prototyping, and consolidated manufacturing processes, leading to cost and time efficiencies.

Q5: What security concerns arise with the increased connectivity of CNC machines?

Increased connectivity introduces cybersecurity risks. Manufacturers must implement robust network security measures, including data encryption, secure access protocols, and regular vulnerability assessments, to protect sensitive manufacturing data and intellectual property.

At a Glance

Related Blogs

Shed No. 10, Fresh Express Warehouse,

Road B1, Dubai Investments Park 1,

Dubai, UAE.

+971 43807099

+971 563244963

+971 503226480