10.February.2025

What Is Custom Steel Fabrication? A Comprehensive Overview

Did you know that steel is the most recycled material on Earth, at an impressive 60 percent?

This means that whatever you see in your house, car, or office may have belonged to some other structure when it started. It could have been part of a battleship or an old bridge. Steel's versatility can be credited to custom steel fabrication, a process whereby raw steel is converted to manufacture products suitable for their intended applications.What is custom steel fabrication, how does it work, its advantages, and all its possible uses in most industries shall be the matter of our discourse. En route to these objectives, some lesser-known facts about this industry will also be discussed.

At a Glance

-

What Is Custom Steel Fabrication?

-

The Steps in Custom Steel Fabrication

-

Advantages of Custom Steel Fabrication

-

Applications Across Industries

-

Materials Used in Custom Steel Fabrication

-

New Trends in Custom Steel Fabrication

-

Challenges in Custom Steel Fabrication

-

How to Select the Best Custom Steel Fabrication Partner

What Is Custom Steel Fabrication?

Custom Steel Fabrication is a procedure through which steel can be molded, cut, and assembled to form specific structures or components. Custom fabrication stands out in direct opposition to mass production which has products turned out in quantities of a similar sort.

This process is most common in the production of everything from skyscraper structural beams to fine, precision-crafted steel furniture, with the objective of getting each piece to be useful and fit its intended purpose.

The Steps in Custom Steel Fabrication

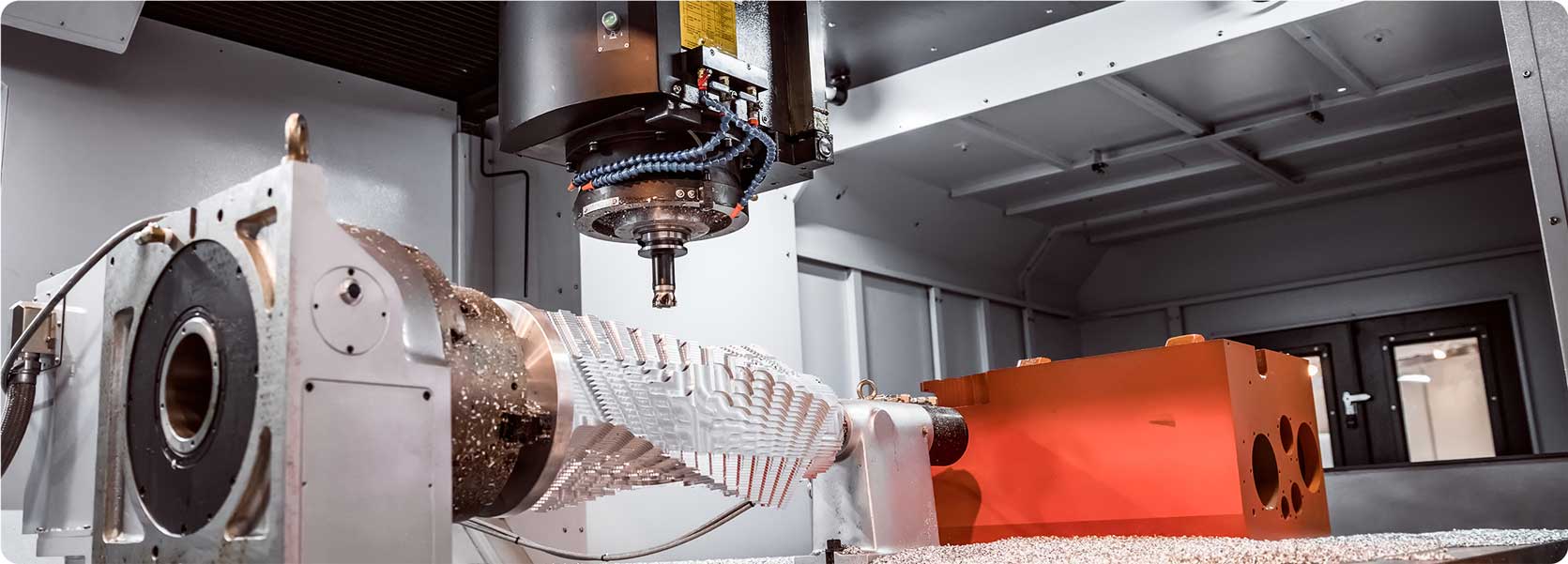

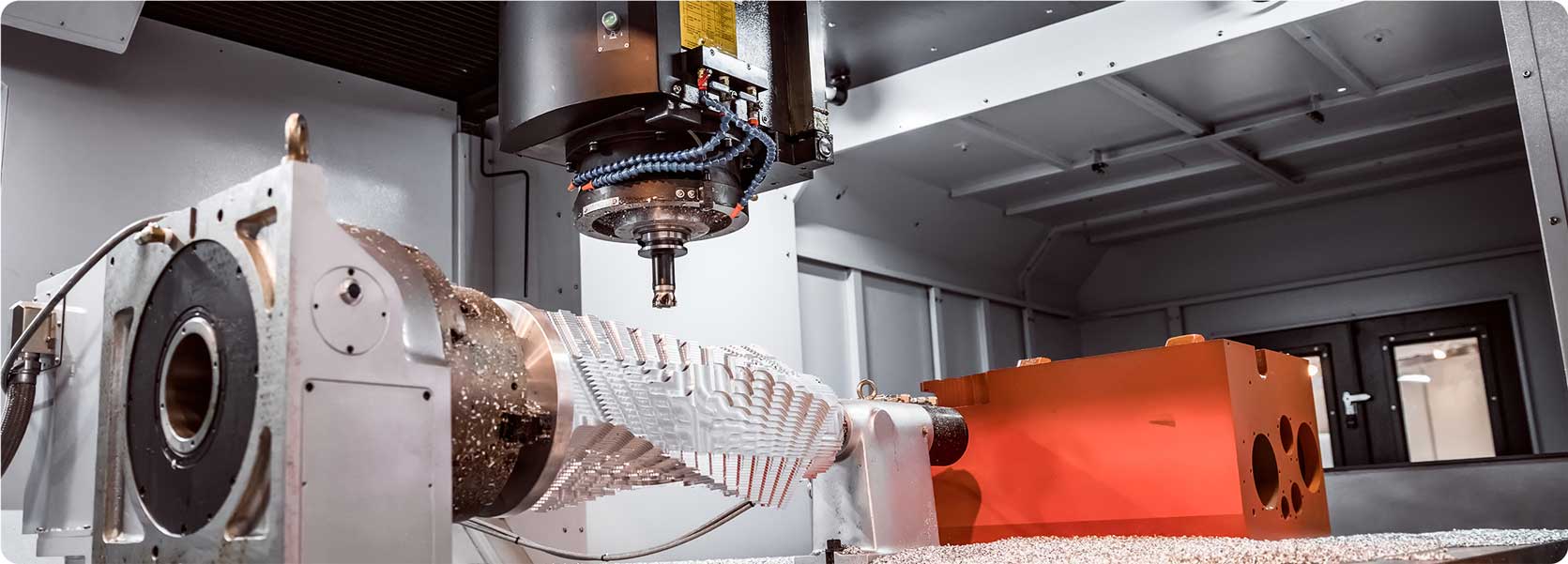

1. Cutting

The first step in custom steel fabrication is cutting raw steel into precise shapes. This can be done through traditional tools such as saws or more advanced methods like laser and waterjet cutting. CNC machines are used most of the time to ensure absolute precision, with no guesswork and a reduction in waste.

2. Bending

This bending of the steel to shape is one of the critical steps, requiring skill and high-tech equipment. The creation of everything from gentle curves to sharp angles is made possible through press brakes and rollers. It's all about keeping the integrity of the structure of the steel intact and getting it exactly to specifications.

3. Welding

The final process in welding is where separate pieces of steel bond to make a single, robust structure. Skilled professionals master the techniques of TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. To weld solid and strong joints, these techniques help. It takes expertise and talent because even the slightest error would compromise the strength of the final product.

4. Finishing

The finishing process involves polishing, sandblasting, and applying protective coatings. It not only gives a finer appearance to the steel but also enhances its resistance against corrosion and other environmental effects.

Advantages of Custom Steel Fabrication

1. Unmatched Durability

Custom steel products are made to last. As a material, steel is strong in itself, but the fabrication process ensures that every piece is optimized for its function, making it even sturdier.

2. Tailored Designs

With custom steel fabrication, you can design and make products that fit specific needs. Whether you have complex designs or large-scale industrial frameworks, this process will be able to accommodate any requirement.

3. Cost-Effectiveness in the Long Run

While custom steel fabrication might have higher upfront costs, it is often more economical in the long term. The precision and quality of custom steel fabrication cut down on the need for repairs and replacements, saving you money over time.

Applications Across Industries

1. Construction

Custom steel fabrication is a must in construction, as it manufactures every single beam and column down to staircases and railings. Its strength and versatility make it ideal for any residential or commercial project.

2. Manufacturing

In manufacturing, custom steel components are used to build machinery, conveyor systems, and molds. They are intended to be durable enough for industrial use but still exhibit high performance.

3. Energy Sector

The energy sector uses custom-fabricated steel for pipelines, wind turbines, and solar panel mounts. Steel is the first choice in this industry since it can withstand extreme conditions.

4. Automotive Industry

From chassis to engine components, steel fabrication plays a crucial role in producing long-lasting and fuel-efficient vehicles.

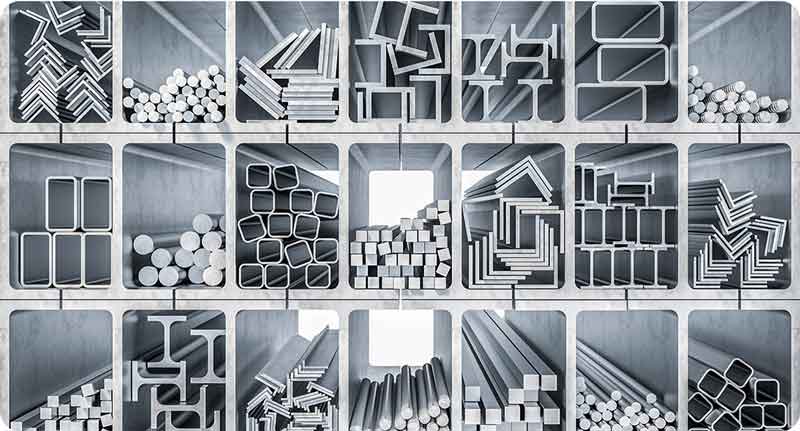

Materials Used in Custom Steel Fabrication

Custom steel fabrication uses a variety of steels that are chosen for their particular properties:

Carbon Steel: It is extremely strong and very cheap; thus, it finds broad application in structural components.

Stainless Steel: This exhibits a strong resistance to corrosion along with a mirror-bright finish. Therefore, this material is highly suited to industrial applications as well as aesthetic requirements.

Alloy Steel: With some more added elements like chromium or nickel, alloy steel can have definite properties that would be essential for special uses.

Various aspects like strength and weight, which also consider environmental factors, are used at selection to ensure that the final output meets its performance requirements.

New Trends in Custom Steel Fabrication

Automation and Robotics

Automation is revolutionizing the custom steel fabrication industry. Robots and automated systems are used for high precision, less production time, and reduced cost.

Sustainability Practices

As sustainability is becoming a priority, industries have been adopting green practices among steel fabricators. This includes recycling the scrap steel, using energy-efficient machinery, and avoiding wastage.

Advanced Coatings

New coating technologies are coming in to enhance the durability and weather resistance of steel. Especially in construction and energy, this new innovation can boost its strength since it can withstand severe conditions.

Challenges in Custom Steel Fabrication

Custom steel fabrication, although beneficial in many ways, has its disadvantages that require careful maneuvering.

Material Integrity: It is important to note that quality steel is of prime importance because even slight imperfections might mar the final product. Buried defects, such as structural or surface defects, may break down when subjected to tension, thus making stringent tests impossible to avoid. Again, these tests consume a lot of time and contribute to costs.

Labor Costs: Custom fabrication requires skilled labor, and expertise does not come cheap. Processes like precision cutting and welding demand human expertise that automation cannot entirely replace. This reliance on skilled workers often drives up project costs, especially for intricate designs where even small errors can lead to expensive rework.

Raw Material Prices: Prices fluctuate with the whims of globalization, supply chains, and all sorts of political developments affecting steel globally. With most of these raw material fluctuations come sudden price shocks, often ravaging project budgets. Often fabricators have to plot strategies with clients over absorbing this level of raw material fluctuations themself.

Complex Specifications: Generally, complex designs or certain client specifications need advanced technology and careful planning. Lack of precision at every step makes the process suffer delays or a cost overrun in the actual process.

Challenges being significant, the industry after all handles them through innovation, much better planning, and incorporating technology to make custom steel fabrication a sure, efficient practice.

How to Select the Best Custom Steel Fabrication Partner

When choosing a partner in custom steel fabrication, take these factors into account.

Know-how: The company should have a history of offering excellent solutions for custom steel products.

Technology: Make sure they use advanced equipment and techniques for precision and efficiency.

Customer Support: A good partner will ensure open communication and cooperation during the project.

Experience Precision and Reliability with Brightsun Industries. From quality materials to expert craftsmanship, we deliver results you can count on.

Get in touch to start your custom steel journey.

Frequently Asked Questions

1. What is custom steel fabrication?

Custom steel fabrication is the process of cutting, bending, and assembling raw steel to create specific structures or components tailored to unique requirements. Unlike mass production, it allows for customized designs and precise functionality.

2. How is custom steel fabrication different from standard steel fabrication?

Standard steel fabrication focuses on producing common steel components in bulk, whereas custom steel fabrication is tailored to meet specific design and structural needs for unique projects.

3. What industries use custom steel fabrication?

Custom steel fabrication is used in industries such as construction (beams, staircases, railings), manufacturing (machinery, conveyor systems),

energy (pipelines, wind turbines, solar panel mounts), automotive (chassis, engine components)

4. What are the main steps in custom steel fabrication?

The key steps include Cutting – Using saws, laser cutting, or CNC machines for precise shaping, Bending – Press brakes and rollers shape the steel without compromising integrity ,Welding – Joining steel parts using MIG or TIG welding techniques , Finishing – Sandblasting, polishing, and applying protective coatings for durability.

5. What materials are used in custom steel fabrication?

Commonly used materials include , Carbon Steel – Affordable and strong, ideal for structural applications, Stainless Steel – Corrosion-resistant with a polished finish, suitable for industrial and decorative uses , Alloy Steel – Enhanced properties with elements like chromium or nickel for specialized applications.

10. How can I start my custom steel fabrication project?

Get in touch with a reliable fabrication company like Brightsun Industries to discuss your project requirements, material choices, and design specifications.

Related Blogs

-

-

10.February.2025

Why CNC Lathes Are Essential in Modern Manufacturing: A Deep Dive

At a Glance

-

What Is Custom Steel Fabrication?

-

The Steps in Custom Steel Fabrication

-

Advantages of Custom Steel Fabrication

-

Applications Across Industries

-

Materials Used in Custom Steel Fabrication

-

New Trends in Custom Steel Fabrication

-

Challenges in Custom Steel Fabrication

-

How to Select the Best Custom Steel Fabrication Partner

Related Blogs

-

-

10.February.2025

Why CNC Lathes Are Essential in Modern Manufacturing: A Deep Dive