21.May.2025

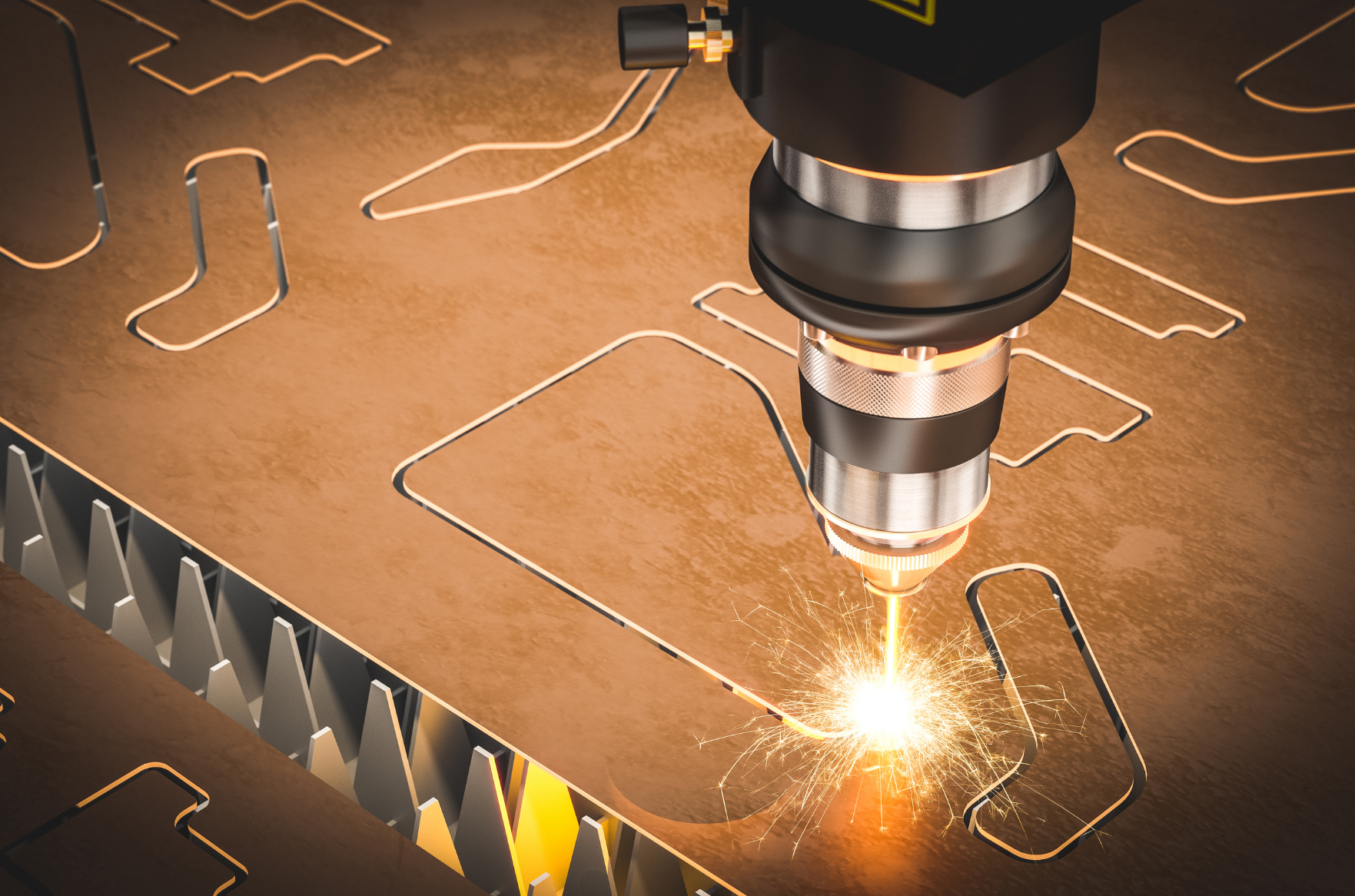

Metal Machining Services Explained: Precision, Speed & Reliability

The products we use daily require extraordinary precision to function properly. Metal machining services are crucial in creating components that perform flawlessly, from automobiles to smartphones. These specialized services accurately shape metal parts, often within tolerances finer than a human hair. Let's explore why metal machining services have become essential in modern manufacturing.

At a Glance

What Are Metal Machining Services?

Metal machining services use specialized equipment and tools to cut, shape, and finish metal parts. These processes transform raw metal into functional components for numerous industries. Common machining methods include:

- CNC milling: Using computer-controlled rotating cutters to remove metal

- Turning: Spinning metal while cutting it with tools

- Drilling: Making precise holes in metal

- Grinding: Using abrasive wheels to smooth metal surfaces

- EDM (Electrical Discharge Machining): Using electrical sparks to shape metal

These services create components that fit together perfectly. Without precise machining, machines would operate inefficiently or fail prematurely.

The Growing Importance of Metal Machining Services

As products become increasingly complex, the demand for perfectly crafted parts grows. Modern machines, vehicles, and devices require components manufactured to exact specifications. Metal machining services deliver this precision in several key ways:

Extreme Accuracy

Modern metal machining services can work with tolerances as small as 0.001 inches. This means parts fit together perfectly, reducing wear and tear. In industries like aerospace, even tiny mistakes can cause big problems. Quality machining services help prevent these issues.

Consistent Quality

Manufacturing today means making the same part thousands or millions of times. Each part must be identical to the others. Metal machining services use computer-controlled systems to ensure every piece meets the same high standards. This consistency is crucial for modern assembly lines.

Complex Designs

New products often have complicated shapes that would be impossible to make by hand. Advanced metal machining services can create these complex designs using 5-axis machines that can approach the work from many angles. This ability lets designers create better products with fewer limitations.

Industries Relying on Metal Machining Services

Many important industries depend on precise metal machining services:

Oil and Gas Components

The oil and gas industry demands robust and reliable metal components that can endure high pressure, extreme temperatures, and corrosive environments.

Precision machining is used to manufacture critical parts such as valves, connectors, and drill components that ensure safe and efficient operation in exploration and refining processes.

Even a minor error in these parts could lead to costly system failures or environmental hazards.

Aerospace and Defense

Airplanes and spacecraft require incredibly precise parts that can withstand extreme conditions. Metal machining services create components with exact specifications that help these vehicles operate safely. Even small flaws could lead to serious problems, making precision essential.

Automotive Manufacturing

Cars contain hundreds of machined metal parts that must work together perfectly. From engine components to transmission parts, metal machining services help create vehicles that run smoothly and safely. As cars become more efficient and complex, the need for precision machining grows.

Medical Devices

Medical equipment often requires tiny, precise metal parts. Surgical tools, implants, and diagnostic machines all rely on quality metal machining services. These parts must meet strict standards since people's health depends on them working correctly.

Electronics and Technology

Modern electronics need small metal housings and components. Metal machining services create these parts with the precision needed for today's slim devices. As technology gets smaller, the machining must be even more precise.

The Evolution of Metal Machining Services

Metal machining has changed greatly over time:

From Manual to Automated

In the past, skilled workers operated machines by hand to create metal parts. Today, computers control most machining equipment. This change has made metal machining services faster, more precise, and more consistent.

Advanced CNC Technology

Computer Numerical Control (CNC) machines have transformed metal machining services. These machines follow digital instructions to create perfect parts with minimal human involvement. Modern 5-axis and multi-tasking machines can create complex parts in a single setup.

Smart Manufacturing

Today's best metal machining services use connected systems that share data between machines. This "smart manufacturing" approach helps find problems early and improve quality. Machines can automatically adjust settings to maintain precision.

The Benefits of Outsourcing Metal Machining Services

Many companies choose to use outside metal machining services rather than doing the work themselves. This approach offers several advantages:

Access to Specialized Equipment

Quality machining equipment is expensive. By using external metal machining services, companies can access advanced machines without a huge investment. This makes precision manufacturing available to more businesses.

Technical Expertise

Professional metal machining services have skilled staff who understand the science of cutting metal. They know which tools and methods work best for different materials and designs. This expertise leads to better parts and fewer problems.

Cost Efficiency

Setting up an in-house machine shop is costly. Outsourcing to metal machining services often saves money, especially for companies that don't need machining all the time. It turns a fixed cost into a variable one that changes with production needs.

Sustainable Practices in Metal Machining Services

Modern metal machining services are becoming more environmentally friendly:

Reducing Waste

Advanced machining techniques create less scrap metal. This reduces waste and saves materials. Some metal machining services also recycle metal chips and cutting fluids.

Energy Efficiency

Newer machines used by metal machining services use less power than older models. Some shops also use energy monitoring systems to find ways to cut electricity use.

Safer Cutting Fluids

Traditional cutting oils could harm the environment. Today's metal machining services often use safer, biodegradable options that work just as well without the environmental impact.

The Future of Metal Machining Services

Metal machining services continue to evolve with new technology:

Hybrid Manufacturing

Some advanced metal machining services now combine traditional machining with 3D printing. This approach allows for even more complex parts and less material waste.

AI and Machine Learning

The newest metal machining systems use artificial intelligence to improve quality. These smart systems can predict tool wear and suggest adjustments before problems occur.

Micro-Machining

As products get smaller, metal machining services are developing ways to create tiny parts with incredible precision. Some can now machine features smaller than the width of a human hair.

Conclusion

Metal machining services form the foundation of modern manufacturing. They create the precise parts needed for everything from airplanes to smartphones. As technology advances, the demand for high-quality machining will only increase. Companies that understand the value of precision machining gain an edge in today's competitive market.

Choose Brightsun Industries for Your Metal Machining Needs

Active since 2006, we at Brightsun are committed to providing the finest quality metal machining and fabrication services in the United Arab Emirates.

Contact us today to discover how our precision machining expertise can help your manufacturing projects succeed.

Frequently Asked Questions

1. What is the difference between CNC machining and conventional machining?

CNC machining uses computers to control tools with exact precision, while conventional machining relies on manual operation and is less precise.

2. What industries benefit most from professional metal machining services?

Aerospace, automotive, medical device, electronics, and defense industries benefit most due to their need for high precision parts.

3. How accurate can metal machining services be?

Top metal machining services can achieve tolerances as tight as 0.0001 inches, depending on the process and material used.

4. What materials can be processed by metal machining services?

Metal machining services can work with aluminum, steel, titanium, copper, brass, and many specialty alloys used in manufacturing.

5. Is it better to have in-house machining or outsource to metal machining services?

Outsourcing to specialized metal machining services is often more cost-effective unless you have consistent, high-volume production needs.

What Are Metal Machining Services?

What Are Metal Machining Services?